Exhibitor Profile

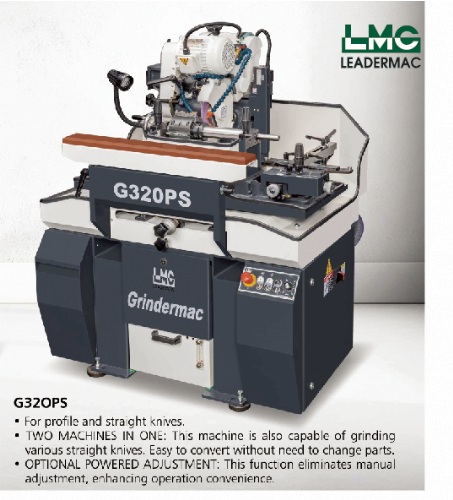

LEADERMAC MACHINERY CO., LTD

The product to be exhibited by LEADERMAC this time are 4-sided moulder with infeeding system, cutter spindle and Surface Pre-working Machine for Edge Glue Manufacture. The new product, Surface Pre-working Machine for Edge Glue Manufacture, also called LMC-723C(2M). This machine works with a special trimming saw blade, which can produce a high-friction surface. And make good quality and longer lifetime edge glue production. Its feature is that it has high efficiency and continuous output, then can achieve high productivity. Also its top spindle defines the thickness and the width first and mills the surface glued by the special trimming saw blade spindle. This kind of process can increase the wood gluing effect in wood composing products. After milling by this machine, the woods will have a high-friction surface. Then we call the finished products as edge glued panels. With edge glued panels, we can produce lots kinds of furnitures. Such as edge glued tables, chairs, counters and walls. With Surface Pre-working Machine for Edge Glue Manufacture, LEADEMAC has taken woodworking to the next level. Customers will be able to make edge glued panels and furnitures whatever they like. And the finished goods all retain the fine qualities.

• Area:

Woodworking Industry

• Booth No:

A205

• Website:

http://www.leadermac.com

• Brands:

LMC LEADERMAC

Exhibitor Press Release

| 2025-10-21 | LEADERMAC - WHOLE LINE SYSTEM |

2025-10-21

LEADERMAC - WHOLE LINE SYSTEM

You may also like

Highest Rated Exhibitors

VRG KIEN GIANG MDF JOINT STOCK COMPANY

CONG TY TNHH DAI PHUC VINH

THUAN HIEN ONE MEMBER CO., LTD

VETTA CO., LTD.

LIDO WOOD JOINT STOCK COMPANY

CÔNG TY CÔNG NGHIỆP TNHH SAGACITY SAILING

YALIAN MACHINERY CO., LTD.

NANXING MACHINERY CO.,LTD

DIEFFENBACHER GMBH

HOLZ-SCHNETTLER SOEST IMPORT - EXPORT GMBH

WEITMANN & KONRAD GMBH & CO. KG

FRITZ EGGER GMBH & CO. OG

BLUM VIETNAM LTD.

LEADERMAC MACHINERY CO., LTD

GERMAN PAVILION

TAIWAN WOODWORKING MACHINERY ASSOCIATION

AMERICAN HARDWOOD EXPORT COUNCIL

ADVANTAGE AUSTRIA

THUONG NGUYEN CO., LTD

VIRGINIA DEPARTMENT OF AGRICULTURE AND CONSUMER SERVICES

BEIJING LOYAL INTERNATIONAL FAIR CO., LTD.

BLUE-VENT PTE LTD

AN BINH SAW BLADE COMPANY LIMITED

ARDEN PRECISION TECHNOLOGY CO., LTD

GOODTEK MACHINERY CO., LTD.

BARBERÁN, S.A.

JIANGSU HIMEI NEW MATERIAL CO., LTD.

QUEBEC WOOD EXPORT BUREAU (QWEB)

QINGDAO GIANTWAY MACHINERY CO., LTD

SUSTA, SOUTHERN UNITED STATES TRADE ASSOCIATION

Back

Exhibitor Inquiry

Exhibitor Inquiry