Login

Contact

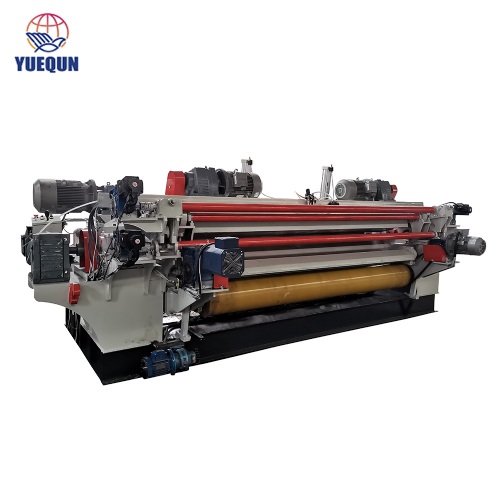

Description

Our complete MDF/HDF production lines with production capacity from 110 to 500 CBM/day take wood or other plant fibers as raw materials to produce 650-880kg/m3 fiberboards by applying urea formaldehyde resin and hot-pressing. MDF/HDF has excellent characteristics of compact and flat surface, uniform core and easy mechanical processing of outer surface/sides, which is widely used in the fields of furniture manufacturing, building decoration, packaging and so on.

Main features

-Advanced raw material handling equipment to obtain high-quality fibers;

-Flash dryer used to ensure stable moisture content of fibers;

-Advanced mechanical and airflow mat-forming technology to form mats with fine surface and homogeneous structure;

-Excellent hydraulic system with good performance and high efficiency and stability;

-Advanced electrical control technology and components to ensure a stable closed-loop process.

Main features

-Advanced raw material handling equipment to obtain high-quality fibers;

-Flash dryer used to ensure stable moisture content of fibers;

-Advanced mechanical and airflow mat-forming technology to form mats with fine surface and homogeneous structure;

-Excellent hydraulic system with good performance and high efficiency and stability;

-Advanced electrical control technology and components to ensure a stable closed-loop process.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry