Login

Contact

Description

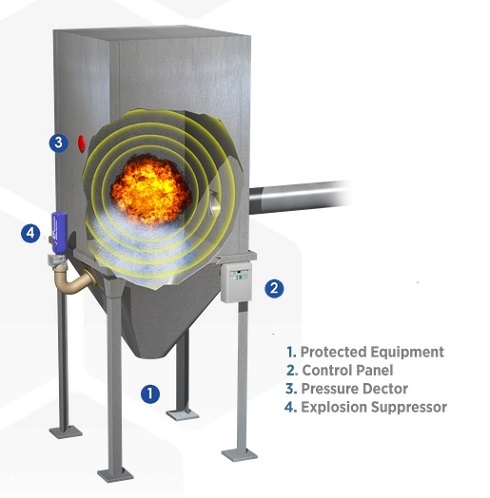

Explosion isolation systems are designed to detect an explosion in a process vessel, and then create a barrier that reduces the risk of the flame/explosion propagation to other interconnected equipment. Such explosion propagation is likely to give rise to an enhanced (more intense) explosion in any connected vessel than would be expected from a simple ignition in that vessel. Explosion isolation is a proven method of reducing the risk of such enhanced explosions, and may be an essential requirement to attain a sufficient risk reduction from the overall explosion protection system.

There are three basic types of explosion isolation systems:

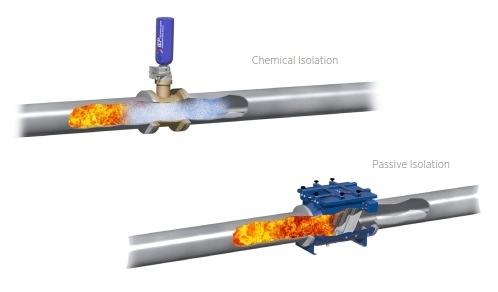

‧ Chemical Isolation – Discharges an explosion suppressant into the duct work that will suppress the propagating flame front.

‧ Active Mechanical Isolation – Triggers the release of a high-speed valve to form a mechanical barrier in the pipeline.

‧ Passive Mechanical Isolation – No additional controls or sensors are usually required for passive.

There are three basic types of explosion isolation systems:

‧ Chemical Isolation – Discharges an explosion suppressant into the duct work that will suppress the propagating flame front.

‧ Active Mechanical Isolation – Triggers the release of a high-speed valve to form a mechanical barrier in the pipeline.

‧ Passive Mechanical Isolation – No additional controls or sensors are usually required for passive.

Highest Rated Products

Back

Product Inquiry

Product Inquiry